#KAORU ISHIKAWA DIAGRAM STATISTICAL PROCESS CONTROL HOW TO#

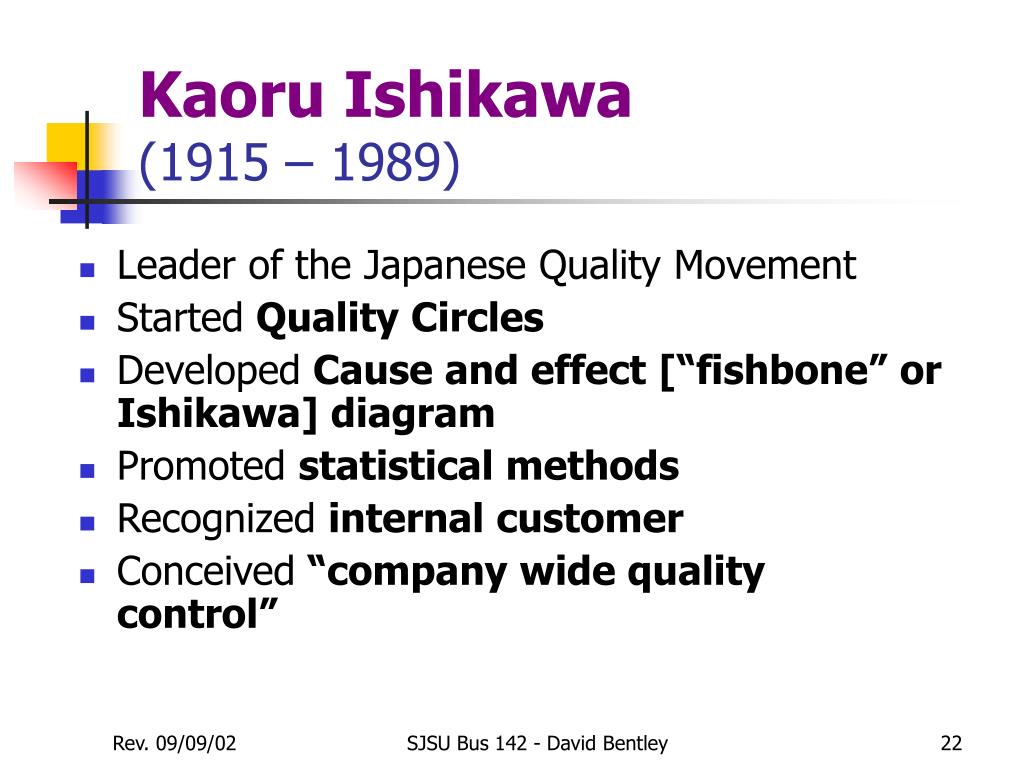

He also wrote we draw limits on the graphs to indicate the standards for evaluation. Fishbone Diagram Kaoru Ishikawa is considered by many researchers to be the founder and first promoter of the ‘Fishbone’ diagram (or Cause-and-Effect Diagram) for root cause analysis and the concept of Quality Control (QC) circles. Covers how to create and use the 7 basic tools of SPC: histograms, cause-and-effect fishbone diagrams, check sheets, Pareto diagrams, run charts, control. in the case of XmR charts, strictly it is an approximation of standard deviation, the does not make the assumption of homogeneity of process over time that the standard deviation makes. Ishikawa wrote the purpose of a control chart is to determine whether each of the points on the graph is normal or abnormal, and thus know the changes in the process from which the data has been collected. The standard deviation (e.g., sqrt(variance) of the mean) of the statistic is calculated using all the samples – or again for a reference period against which change can be assessed.A centre line is drawn at the value of the mean or median of the statistic.For example, in the chart above, the problem for a hospital pharmacy is identified as.

The mean of this statistic using all the samples is calculated (e.g., the mean of the means, mean of the ranges, mean of the proportions) – or for a reference period against which change can be assessed. The Ishikawa diagram is an excellent tool to apply to problem solving.Points representing a statistic (e.g., a mean, range, proportion) of measurements of a quality characteristic in samples taken from the process at different times (i.e., the data).

It is more appropriate to say that the control charts are the graphical device for Statistical Process Control (SPC). Shewhart ) or process-behavior charts, are a statistical process control tool used to determine if a manufacturing or business process is in a state of control. Comparing current data to historical control limits leads to conclusions about whether the process variation is consistent (in control) or is unpredictable (out of control, affected by special causes of variation).Ĭontrol charts, also known as Shewhart charts (after Walter A. Select method: Statistical methods of process and product control are now regarded by the many companies as. Graph used to study how a process changes over time.

0 kommentar(er)

0 kommentar(er)